Call 800-ISO-9000 to Schedule a Demo or Email

The Key to Consistent High-Quality Production

Advance Your Manufacturing Process with MLP

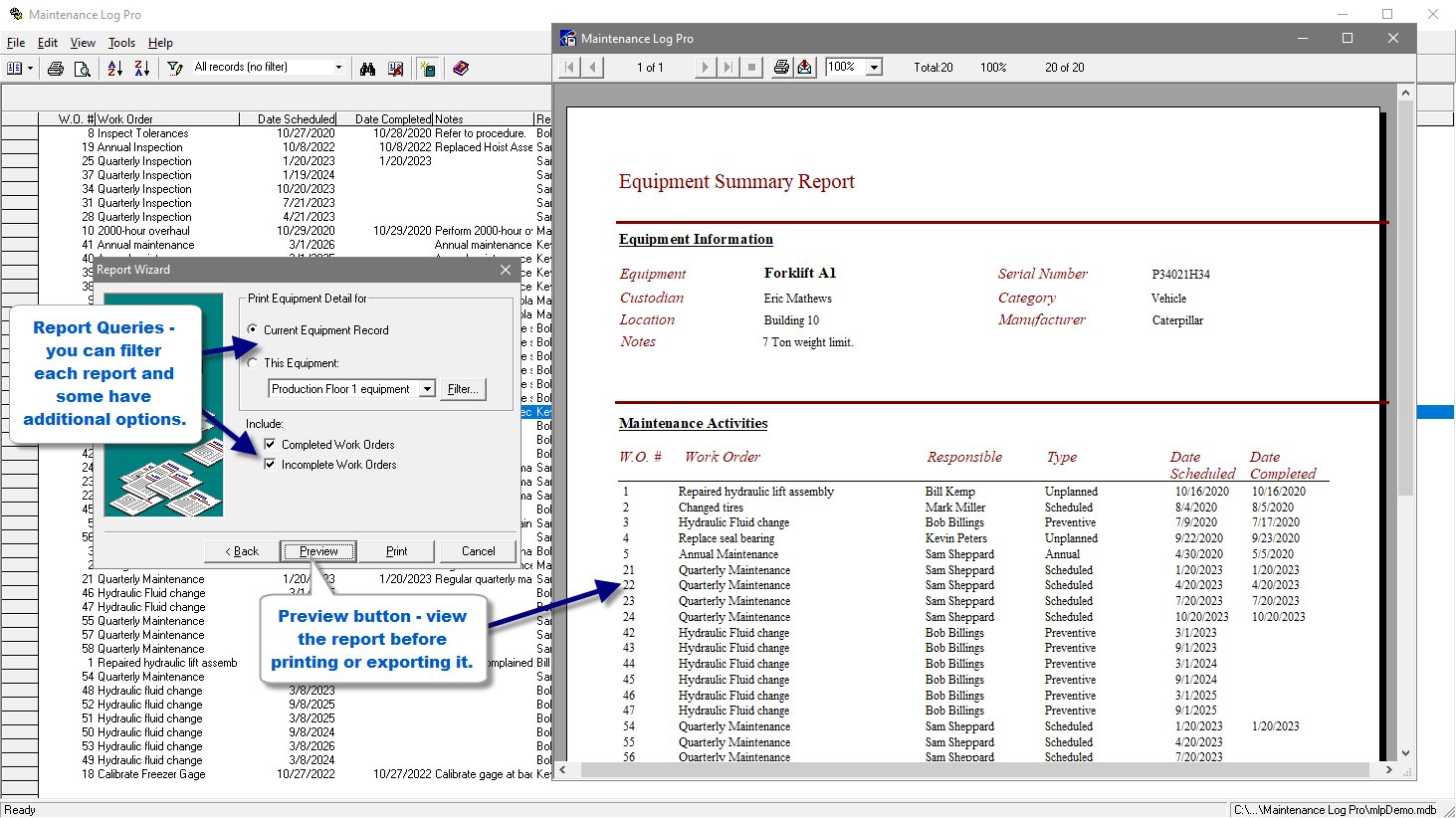

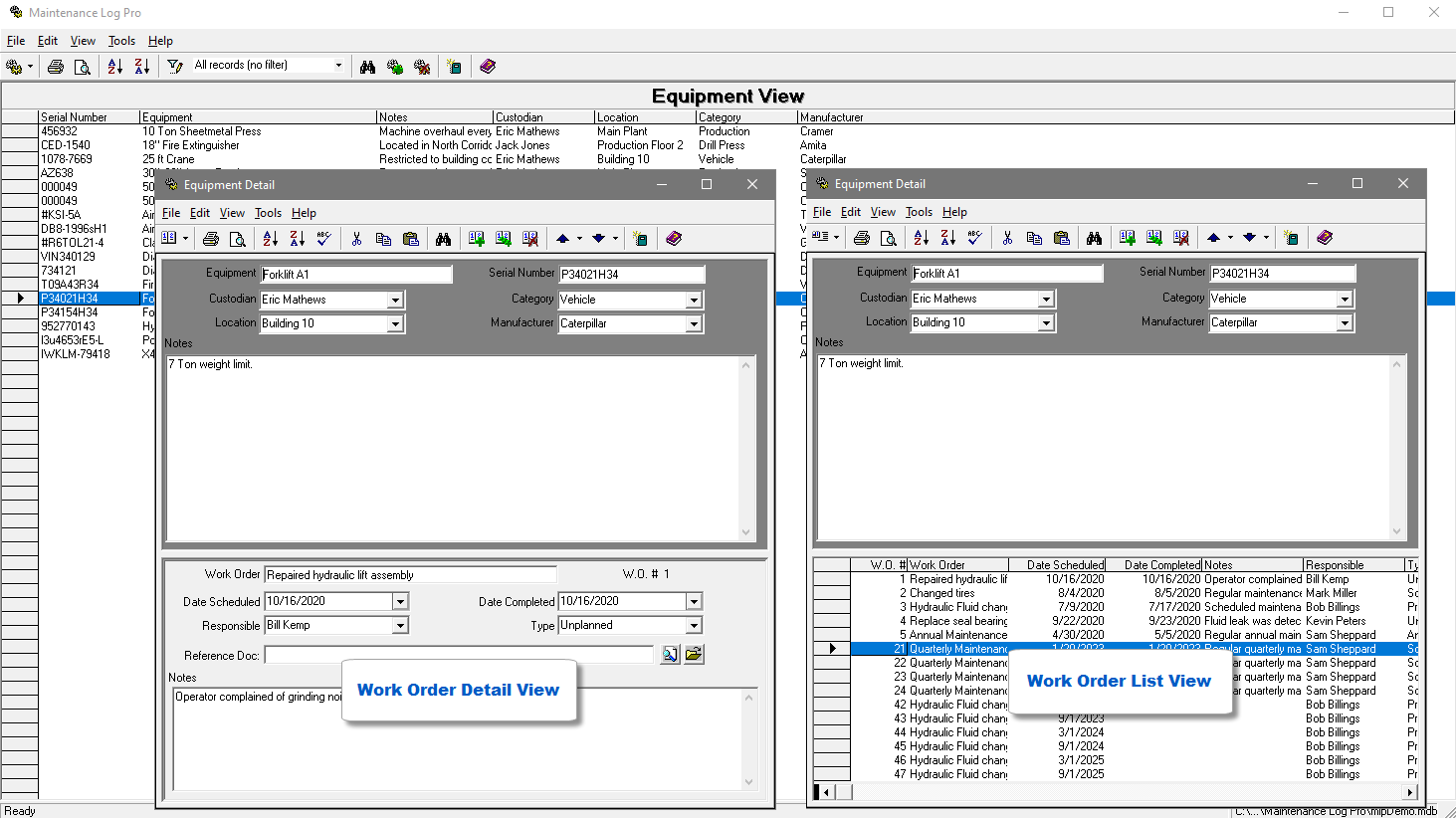

The application’s ample space for data entry allows you to document nearly anything about each piece of equipment. As equipment is serviced, inspection findings can be easily recorded.

![[removal.ai]_f3dc9c8a-f24d-415a-a858-72b841ed2bf0](https://hgint.com/wp-content/uploads/2023/05/removal.ai_f3dc9c8a-f24d-415a-a858-72b841ed2bf0-268x300.png)

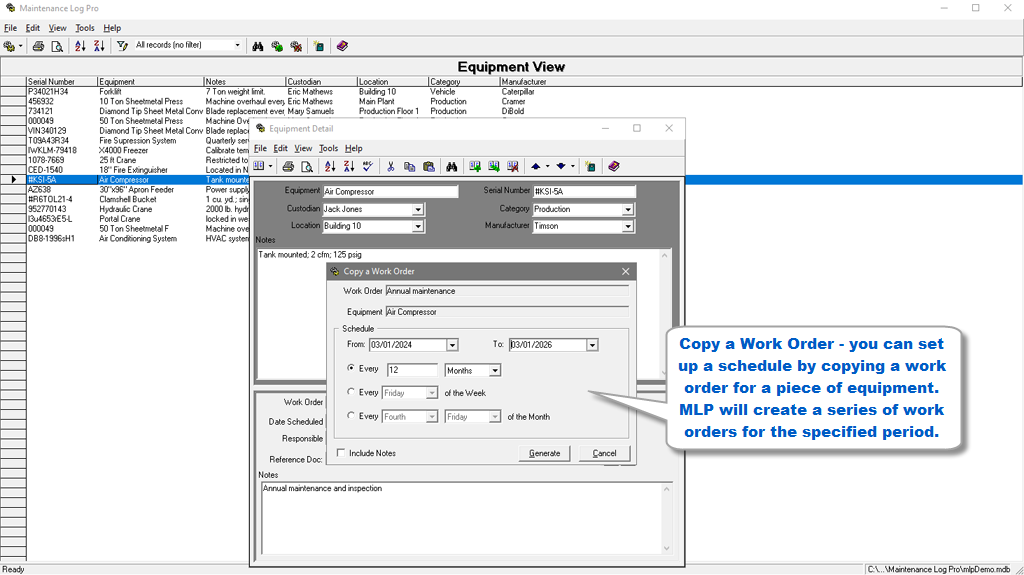

Define a maintenance activity (work order), then schedule it to occur at prescribed intervals. You can also create unplanned work orders

The equipment that comprises your production infrastructure is the foundation of your continued success. Seamlessly maintaining your equipment while keeping historical records of what’s occurred during its lifetime yield both continued production growth, and positive scalable results.

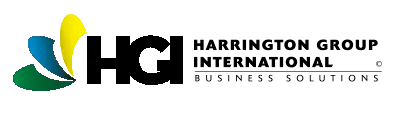

Included reports help to identify scheduled maintenance for your equipment at any location. Instantly print complete maintenance histories of any tool, part, or machine currently in use whether in production, or elsewhere.

Maintenance Tracking

Maintenance Scheduling

Equipment Inventory

Equipment History

Customizable fields

Adjustable data entry sequence

Password Protection

Advanced Reporting

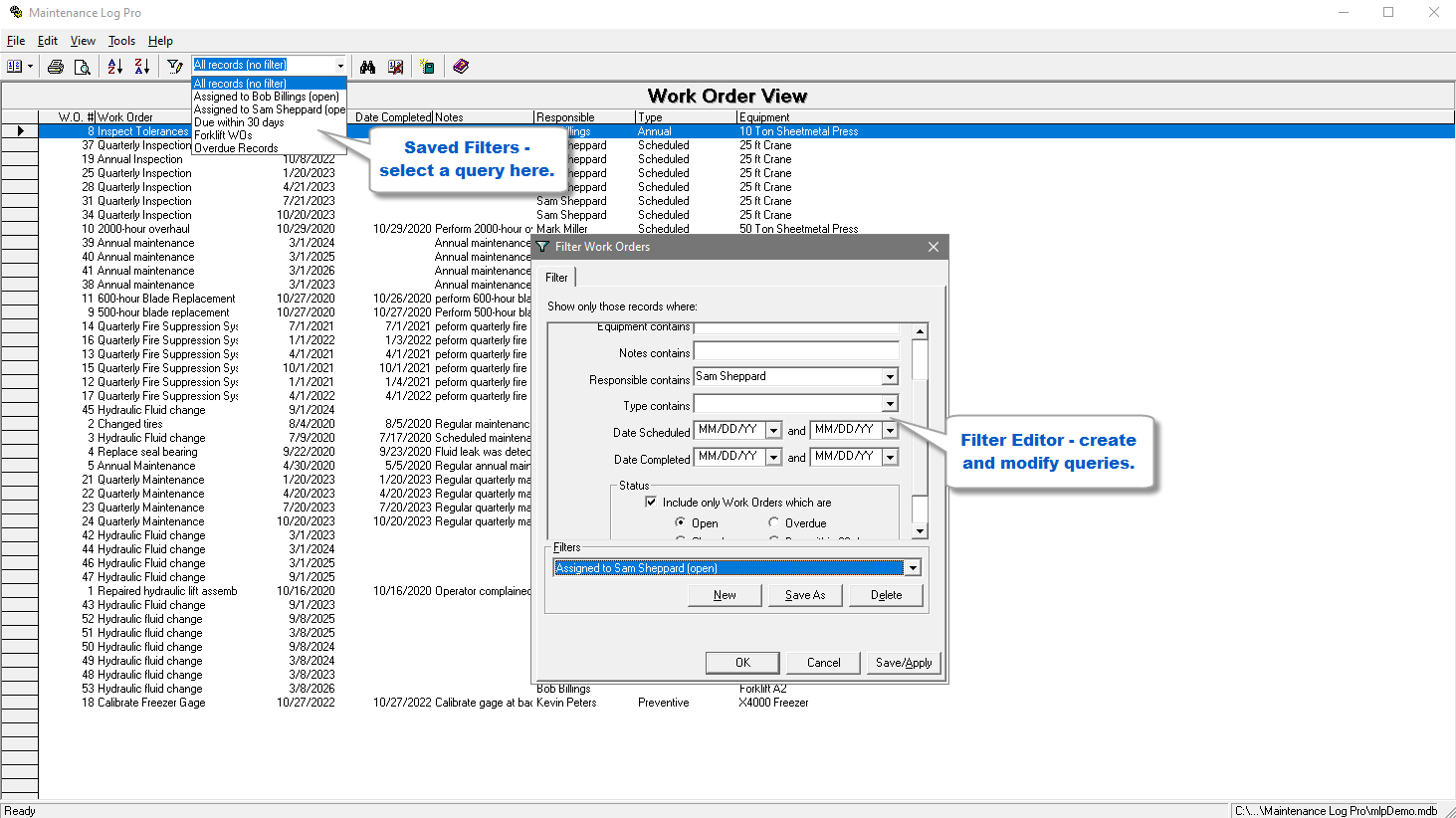

Sophisticated sorts and filter

Fast and specific searching

User Workgroups

Straightforward setup and use