Call 800-ISO-9000 to Schedule a Demo or Email

The Key to Consistent High-Quality Production

Advance Your Manufacturing Process with PPAP

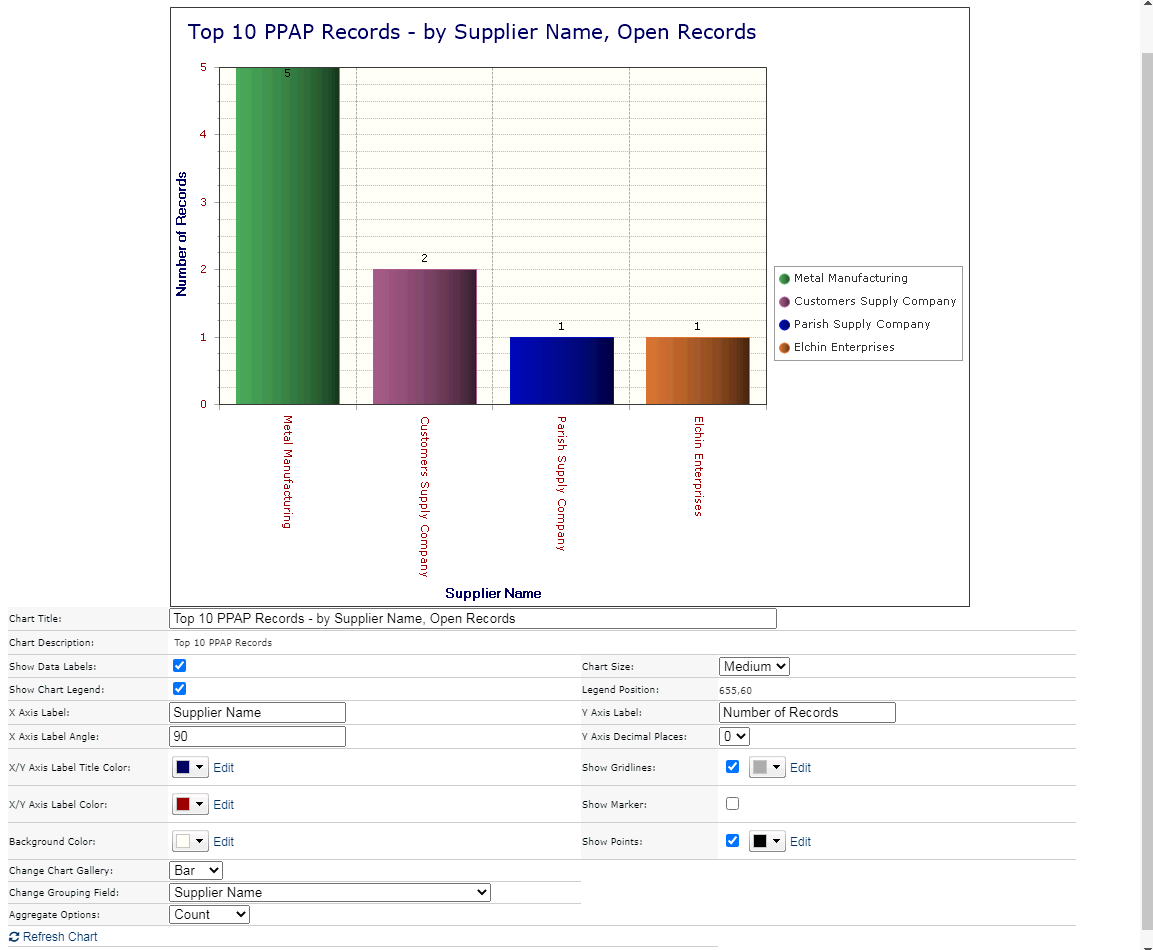

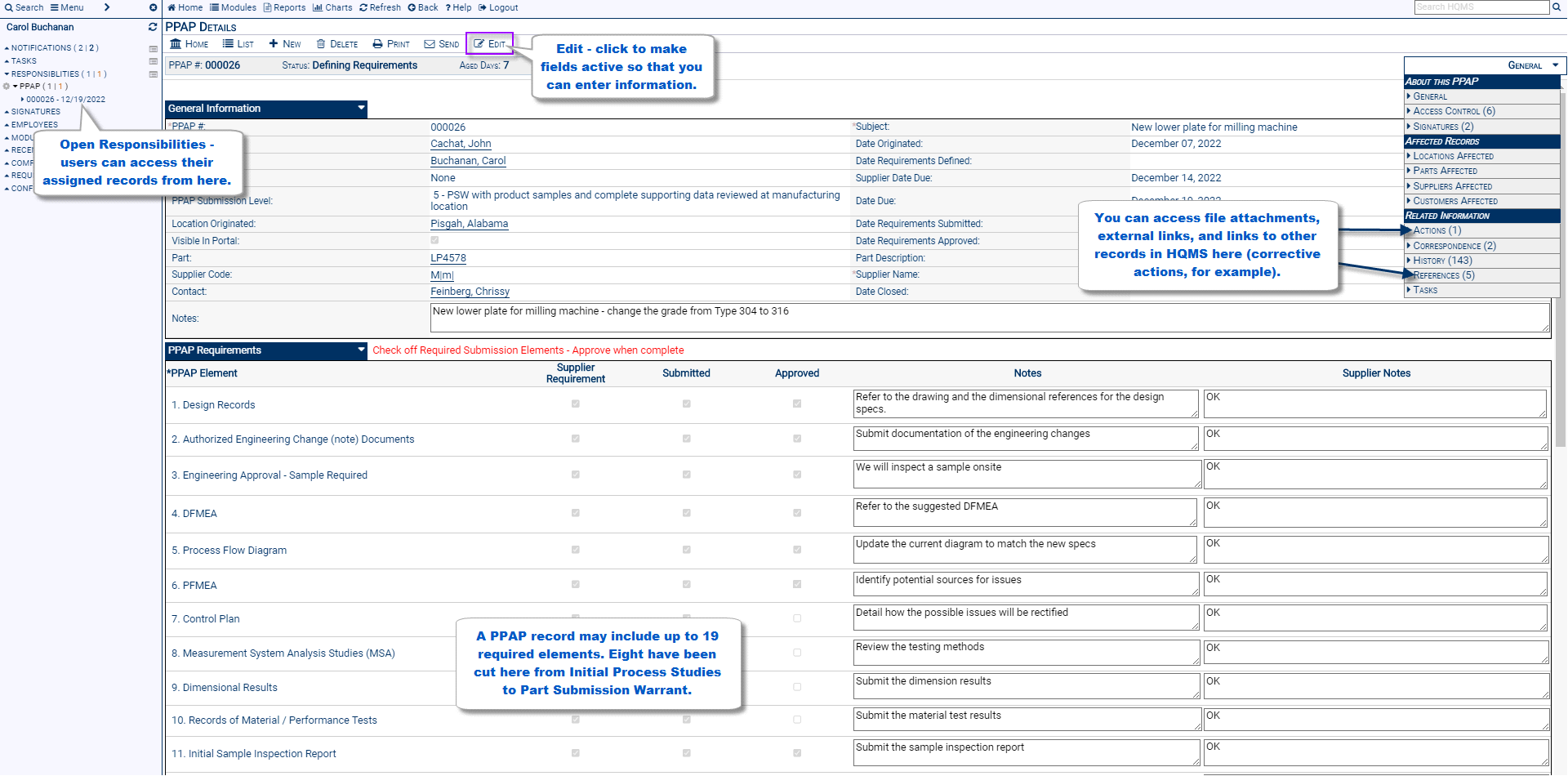

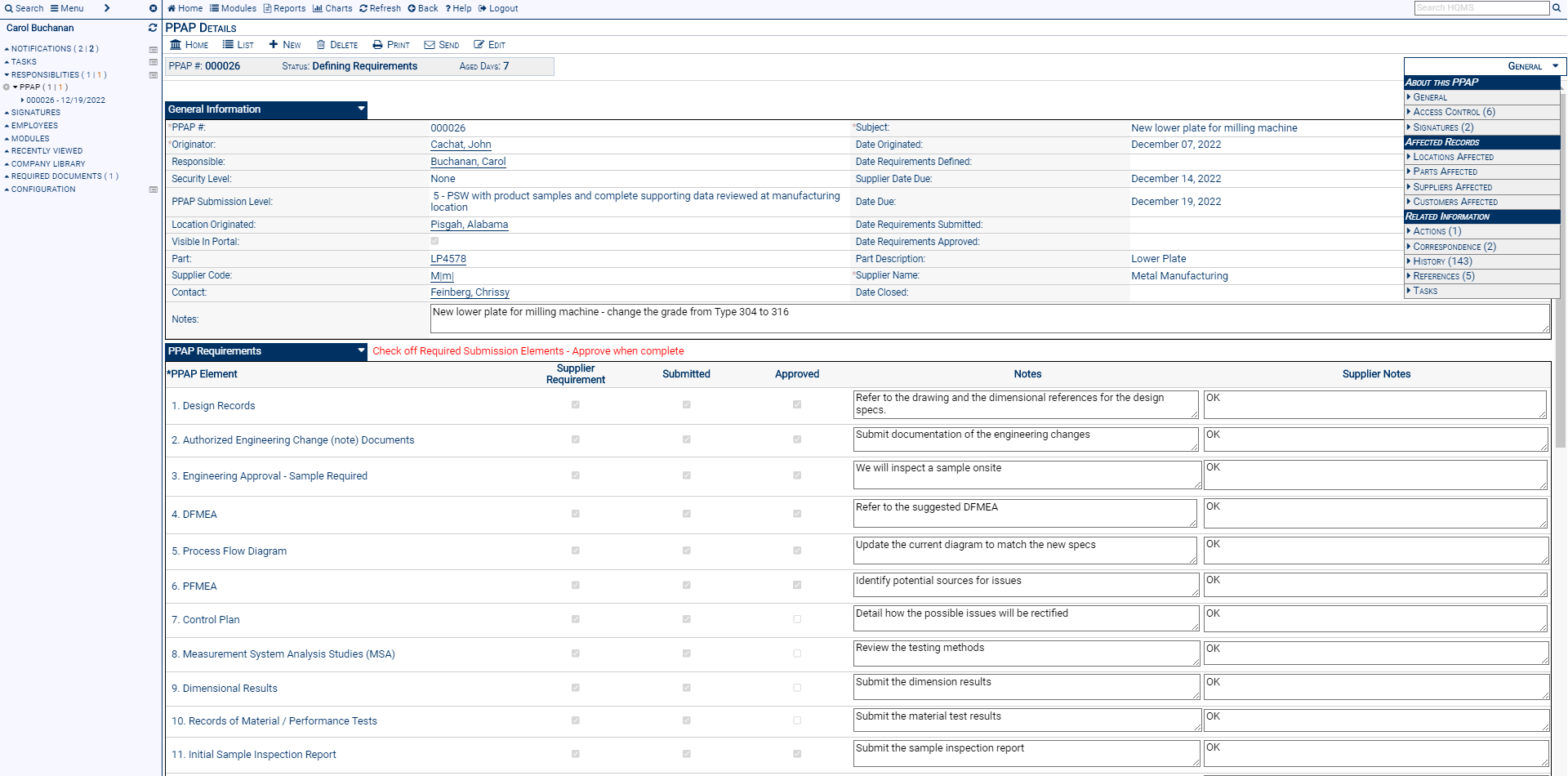

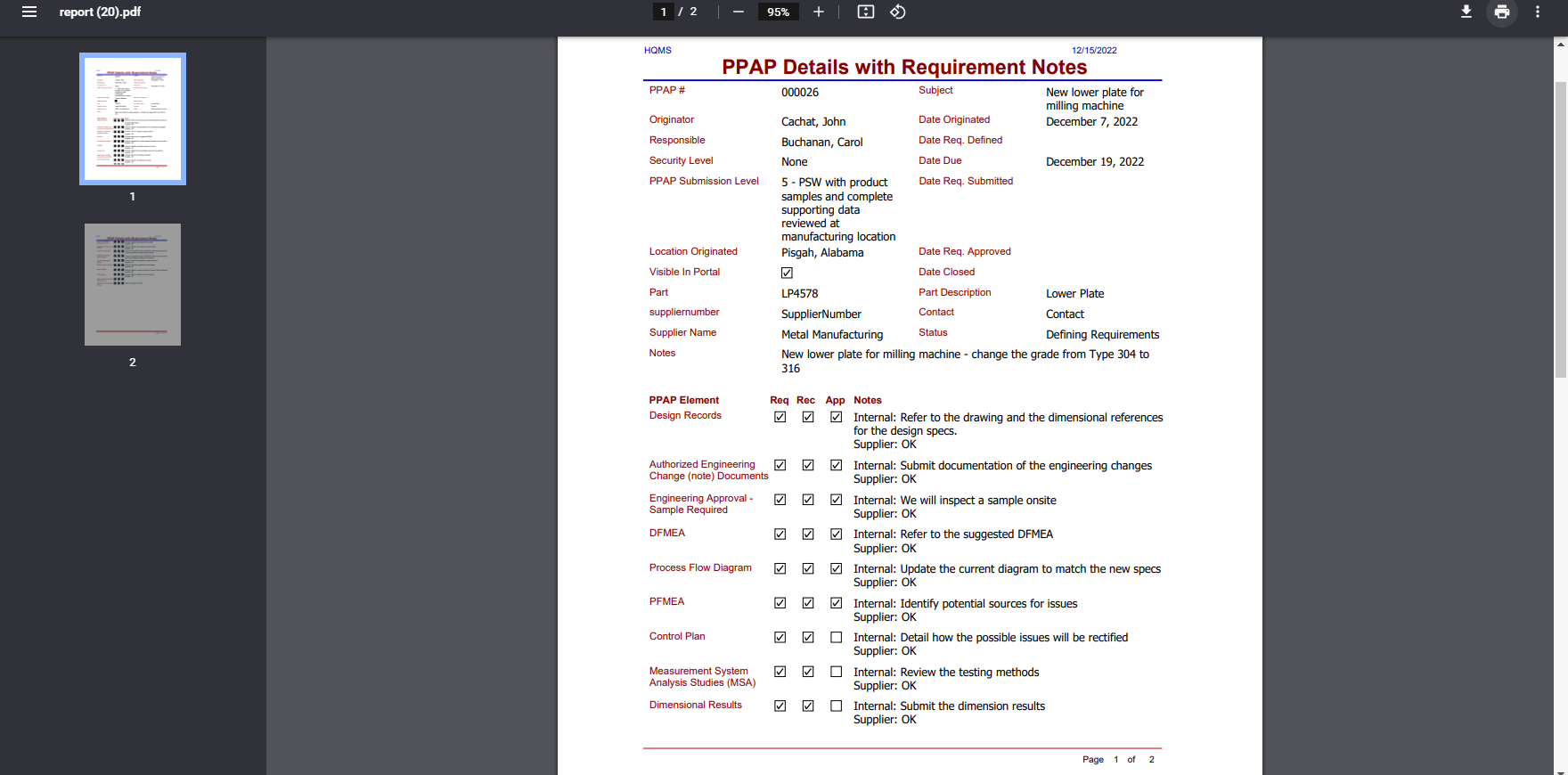

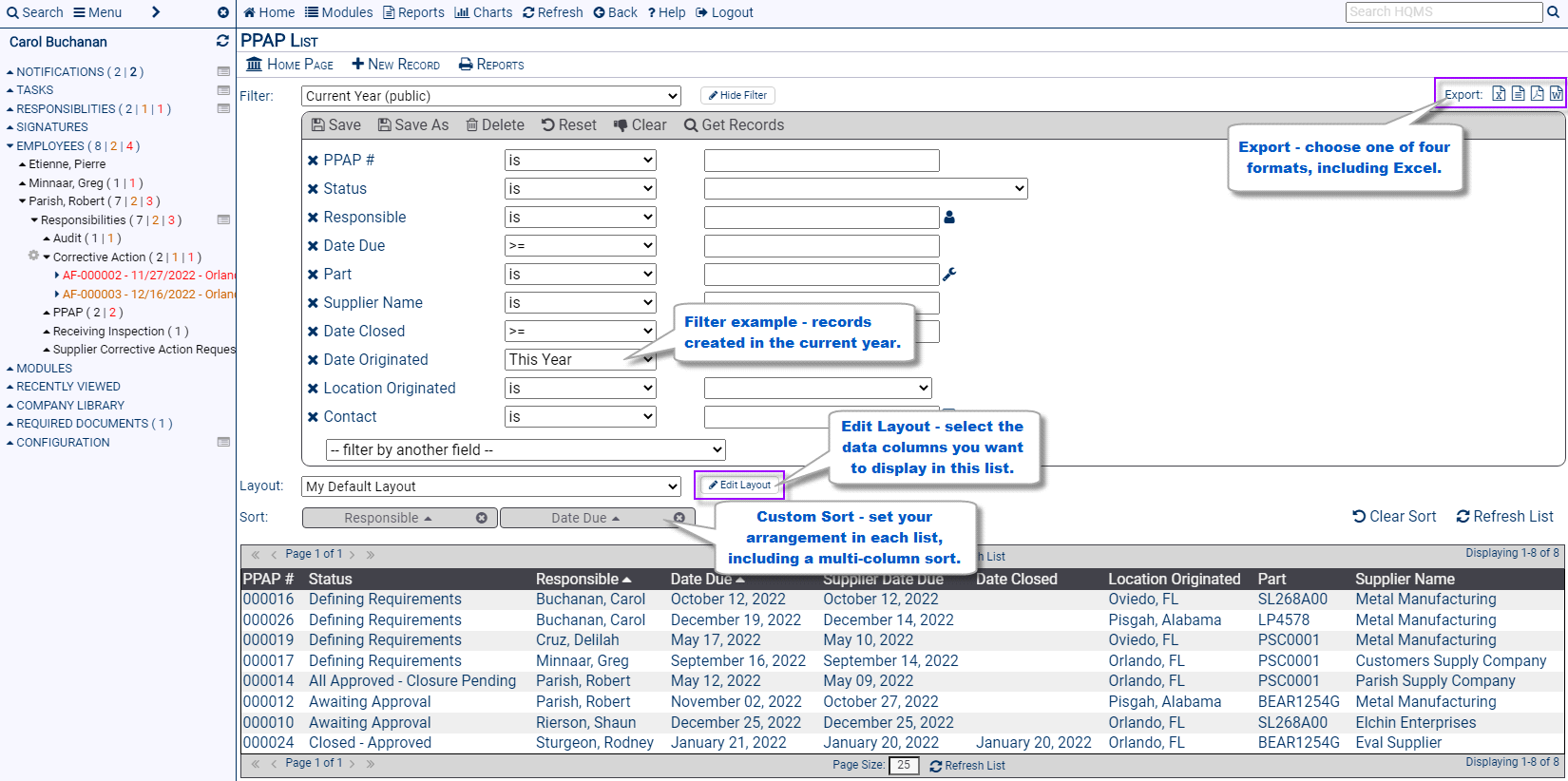

Facilitates Documentation of Communication between Facilities and Suppliers – PPAP Origins Initiate the Approval Process by Selecting a Submission Level and Required Elements, Suppliers Provide Feedback, and the Process is Tracked and Managed until Completion.

Just answering the simple question, “Is this PPAP approved” can be like pulling teeth. Trying to track all the PPAP tasks, across multiple parts and suppliers in a spreadsheet is horrible.

- Production delays caused by missing paperwork

- PPAP submissions are rejected

- Very expensive to solve problems after the start of production

Just answering the simple question, “Is this PPAP approved” can be like pulling teeth. Trying to track all the PPAP tasks, across multiple parts and suppliers in a spreadsheet is horrible.

- Production delays caused by missing paperwork

- PPAP submissions are rejected

- Very expensive to solve problems after the start of production

Manage the entire PPAP process with a robust task list, attachments, and status reporting.

Submission Level capability allows quick identification and management of required submission elements.

Digitally sign off on final requirements specifications, and ensure oversight ranging from management to end user.

Maintain an Approved Part List based on the PPAP approval.

PPAP, FAI, PMA – regardless of what your industry calls it, planning the manufacturing process, risks, and controls improves quality, improves delivery, and reduces costs.

Save time and money by planning for potential issues in advance of production.

Reduce material nonconformance issues by 80% Improve communications with engineering/ manufacturing and external suppliers.

Ensure critical tasks are completed on time and documented correctly.